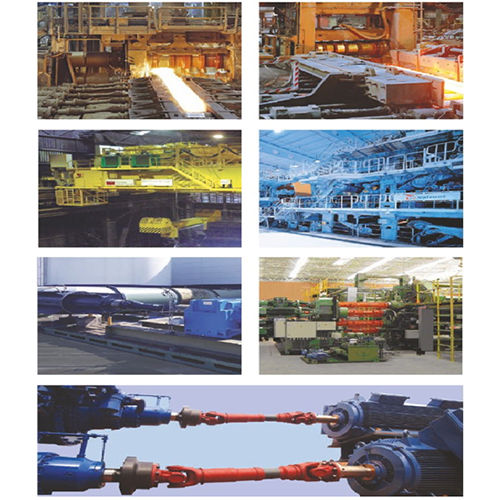

Drive Line Product Range For Industrial Application

Product Details:

X

Product Description

A transmission element such as the constant velocity joint can be used in vehicles as well as in industry applications. Indo Everest Cardan joints and drive shafts are used for applications like:

- Filling machines

- Soil compactors

- Packing machines

- Machine tools

- Textile machines

- Steel Rolling Mills drives

- Printing machines& Paper Mills

- Wind turbines

- Pump drives

- Stationary concrete mixers

- Paper machines

- Test stands

- Thread rolling machine

- Woodworking machines

- Tube Mills

- Power Plants

- Dynamic Balancing Machines

- Sugar mills

- Marine application

- Off Highway & construction

- Heavy Blowers

- Rubber vibrating screen

- Locomotive

Engineered for Reliability and Performance

Our drive line products are meticulously crafted from alloy and hardened steel, ensuring reliability in the most demanding industrial environments. Each component undergoes precision engineering to deliver exceptional strength, durability, and low noise operation while handling extreme torque and speed requirements.

Adaptable Design with Customization Options

We offer customization options for length, bore, and keyway to meet unique application needs. Flexible couplings and universal joints allow for easy alignment and installation, helping you seamlessly integrate our drive lines into varied machinery setups, enhancing operational flexibility.

Comprehensive Service and Support Across India

Comprehensive technical assistance is available both onsite and remotely, supporting installation, alignment, and maintenance requirements. As a manufacturer, supplier, and service provider, we ensure you receive prompt and professional support wherever your facility is located.

FAQ's of Drive Line Product Range For Industrial Application:

Q: How do I select the appropriate drive line for my industrial machinery?

A: Select a drive line by evaluating your application's torque and speed requirements, shaft diameter, and desired length. Our team can assist in customizing bore and keyway dimensions to match your machinery, ensuring optimal fit and performance.Q: What steps are involved in installing and aligning the drive line products?

A: Installation is straightforward. Align the drive line with your machinery's shafts, ensure proper fit of couplings, and secure all connections. Our drive lines are designed for easy installation and precise alignment, and our technicians can provide onsite or remote support as needed.Q: Where are these drive line products manufactured and supplied?

A: All our drive line products are manufactured in India, with supply and service available nationwide. We cater to industrial sectors across the country, offering prompt delivery and local technical support.Q: What lubrication is required for the drive line products, and how often should maintenance be performed?

A: Our drive lines can be grease lubricated or used in an oil bath setup. Regular checks of lubrication levels are recommended depending on operational load, but the low-maintenance design reduces overall servicing frequency.Q: What is the operating temperature range for these drive lines?

A: The drive line products are engineered to perform reliably within an operating temperature range of -20C to +120C, making them suitable for a variety of heavy-duty industrial applications.Q: Can the drive lines be customized for specific length, bore, or keyway dimensions?

A: Yes, we provide full customization options for length, bore, and keyway according to your machinery specifications, ensuring a precise match and enhanced operational efficiency.Q: What are the key benefits of using your drive line products in power transmission applications?

A: Our drive lines offer high efficiency, durable construction, robust torque handling (up to 50,000 Nm), low noise operation, easy installation, and resistance to corrosion. These features ensure reliable, long-lasting performance in industrial power transmission applications.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email