Propeller Shafts for Fire Brigade

Product Details:

X

Product Description

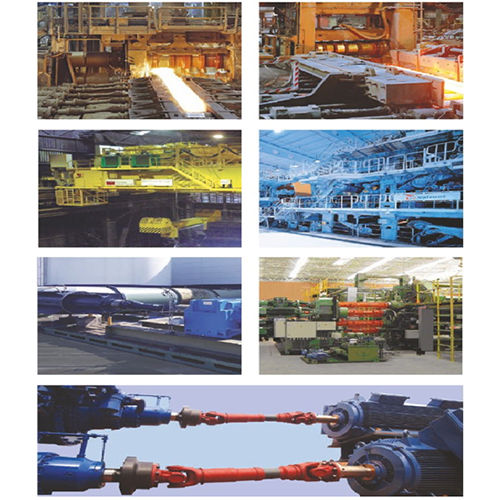

INDO Everest is a Maharashtra, India-based manufacturer and supplier of heavy duty Propeller Shafts For Fire Brigade Trucks to safely deliver torque in between drive and driven elements. It is fabricated as per the automotive and industrial engineering standards that result in high structural accuracy. The universal joints fixed within this transmission element greatly improve the power transfer. Get this premium grade Propeller Shafts For Fire Brigade Trucks from us at a reasonable price range.Superior Manufacturing Process

Each propeller shaft is manufactured through precision machining, ensuring exact dimensions and optimal strength for fire brigade applications. The dynamic balancing method guarantees smooth rotation even at high speeds, minimizing vibration and wear. Quality inspections throughout production maintain the highest reliability standards for every shaft delivered.

Outstanding Durability and Performance

Built to withstand extreme conditions, these shafts deliver reliable power transfer at speeds up to 3000 RPM. They feature comprehensive rust protection and can operate seamlessly from 40C to +150C, making them ideal for firefighting vehicles facing demanding environments and urgent tasks.

Easy Maintenance and Serviceability

Universal joints in these shafts are both grease-lubricated and replaceable, simplifying maintenance routines. This design prolongs the shafts life and reduces downtime, ensuring that fire brigades can rely on their vehicles driveline without concern for premature component failure.

FAQs of Propeller Shafts for Fire Brigade:

Q: How is the precision machining process performed for these fire brigade propeller shafts?

A: Precision machining utilizes advanced CNC equipment to achieve high accuracy in component dimensions, resulting in a robust shaft that meets the specific requirements of fire brigade vehicles. This process ensures consistent quality and enhances performance.Q: What are the advantages of dynamic balancing in these propeller shafts?

A: Dynamic balancing reduces vibration and noise during operation, especially at speeds up to 3000 RPM. This helps maintain smooth driveline performance, extending the shafts lifespan and protecting other drivetrain components.Q: When should the grease-lubricated universal joints be replaced or serviced?

A: Universal joints should be checked during regular vehicle maintenance. If signs of excessive wear or lack of lubrication are observed, it is recommended to replace or re-grease them to maintain optimal performance and prevent failures.Q: Where are these propeller shafts manufactured and supplied from?

A: These propeller shafts are produced by a leading manufacturer, supplier, and service provider located in India, catering to fire brigade and emergency vehicle needs across the region.Q: What benefits does rust protection provide for fire brigade propeller shafts?

A: Rust protection ensures that shafts remain durable even when exposed to moisture or harsh weather, preventing corrosion and degradation over time. This contributes to a longer service life and reliable operation during emergency missions.Q: How should these shafts be used to maximize their temperature resistance capabilities?

A: These propeller shafts are intended to operate reliably between 40C and +150C. Regular inspections and proper lubrication of universal joints will help maintain this temperature resilience, ensuring consistent functionality in extreme conditions.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email